Cryogenics International's computerized deep cryogenic treatment will increase the durability and edge holding ability of knives, blades, slitters, taps, end mills, carbide inserts, reamers, wood working tools of all types, etc.

All high speed steel/HSS and carbide

- Make your blade or tool edge stay sharp much longer

- Go longer between sharpenings

- Remove less material when sharpening

- Reduce micro cracking & edge chipping

- Improve surface finish

- Improve blade strength

- Indexable tool holders are tougher and will not crash as easily.

The Reasons for Enhanced Material Properties

Soft austenite carbon is changed to hard, more stable, abrasion resistant and higher heat-resistant martensite.During the process there is a wide distribution of additional very hard, fine carbides throughout the martensitic matrix of the metal. The particles within the metal matrix develop a more uniform, refined microstructure with greater density. The materials porosity is reduced, due to a denser molecular structure supported by the additional fine carbides and tight lattice matrix. Thermal and mechanical stresses are relieved, reducing the possibility of micro cracking, fractures and edge chipping, the principal causes of tool/blade failure. Because residual stresses affect the ability of the cutting edge to absorb energy, tools that are stress-relieved by the controlled deep cryogenic process are not only highly abrasion resistant but are also more resistant to residual stresses, shock and heat.In the case of steel and steel alloys, the molecular structure of the material is realigned by the reduction of the atoms built-in kinetic energy.

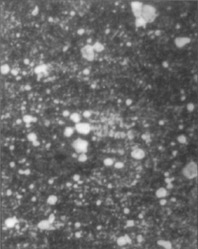

Comparative microphotographs (1000x) of steel samples show the change in microstructure produced by the controlled deep cryogenic process. Uniform, more completely transformed microstructure and less retained austenite at right, is related to improvements in strength, stability and resistance to wear.

Testimonials

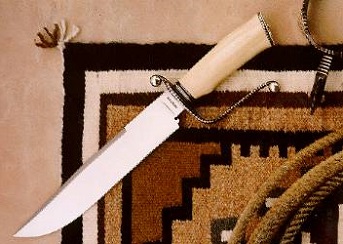

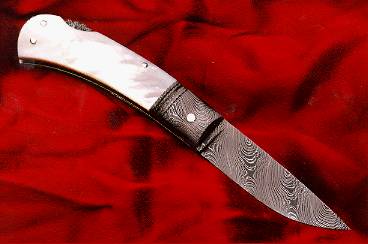

Knives by Tim Hancock

Thank you for your interest in my work. I am a career artisan of fine hand-made knives, bits, and spurs. Quality and artistic appeal are paramount in the construction of my creations. I believe precision hand-made objects are of value today and become the legacy of the future. I am a certified Master Bladesmith of the American Bladesmith Society. I hand-make folders, sheath knives, miniatures, and long blades. My cutlery must meet the demands of superior performance, durability, and be of an elegant and functional design. I feel as a Bladesmith that I can be more diverse in style and steel selection. I work with a variety of steels and also produce my own Damascus steels. The heat treatment of each steel is unique to its performance. Heat treatment is followed by computerized deep cryogenic treatment at -320oF by Cryogenics International to further improve the high standards of the blades. My methods are proven and utilized only after extensive testing.